Morley Glass has invested more than £750,000 to increase its capacity for manufacturing its UK market-leading Uni-Blinds range of integrated window and door blinds by a further 50%.

The investment comes in a year when Morley Glass has produced record volumes of Uni-Blinds, up 46% versus the previous year, reflecting the strong demand that installers are experiencing for the ultra-modern shading and privacy solutions provided by the range.

A new state-of-the-art production line for making insulating glass units complete with ScreenLine Venetian blinds in the cavity has been installed, which means Morley Glass now has three dedicated production lines in all. Installed by long-standing machinery partner Best Makina, these will enable Morley Glass to manufacture up to 6,000 high quality integral blind units every week to support the growth in demand from its nationwide installer base.

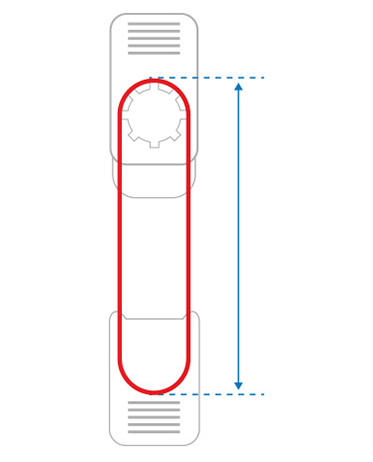

The new plant means the Morley Glass factory in Leeds now incorporates five systems for manufacturing the Uni-Blinds SV System, a cordless sliding Venetian blind that utilises a patented magnetic system to enable long term, effortless operation. This system continues to be the most popular option amongst Uni-Blinds installers, accounting for 70% of all Uni-Blinds sold, driven by homeowners who want a sleek shading and privacy system that will perform reliably over a long service life.

Ian Short, MD of Morley Glass says: “It was only four years ago that we made our last major investment in our manufacturing capacity, but the strength of growth that we have seen for Uni-Blinds, particularly over the past two years, has exceeded our expectations. This required us to commission further new machinery earlier than we had anticipated to ensure we stay ahead of the curve.

“Importantly, it gives our factory the capacity we need to respond to the growth in Uni-Blinds sales over the coming years and supports our change of focus to being 100% an integral blind unit manufacturer. With sustained long term growth over two decades and recent annual growth of around 50%, we know how important it is not to rest on our laurels and we are already planning ahead for the next investments.”

The addition of new production lines at Morley Glass’s 50,000 sq. ft site near Leeds comes hot on the heels of a number of other recent investments by the company. In the second half of 2021, the company replaced its machinery for processing post-consumer waste glass for recycling with a new automated plant capable of handling much larger volumes.

And in the same period, Morley Glass added six Luton vans to its fleet to maintain its industry-leading 10-12 day lead time on Uni-Blinds, when ordered by 10am on Thursdays.

Ian adds: “In a competitive market we never stop investing in our machinery, innovative products and processes to ensure window and door installers get the very best quality products backed by superb service. That’s what our recent investments are all focused on giving our customers total confidence in the Uni-Blinds brand every time they order.”

Morley Glass has grown to become the world’s largest manufacturers of bespoke sealed units with ScreenLine® integral blinds inside. Its products are suitable for all types of windows and doors, including bifold doors, and supplied nationwide to customers with complimentary delivery in the industry’s shortest lead times.