We pride ourselves for being a very open and honest company, but that doesn’t mean after 20 years there are things you may not know about us! Of course, a business is only as good as its people and products, so take a look at these 20 facts about Morley Glass & Glazing and our integral blinds and let us know how many you already knew!

1- We employed just four members of staff when we started out in 1998… today we’re a much bigger team of 70!

2- Our 58-metre long sealed unit production line was the first Best Makina fully-automated sealed unit assembly line to be installed in the UK and arrived in Leeds with a vehicle escort from Turkey

3- Our current factory is actually the fourth premises we’ve had in 20 years. Can you remember the other three?

4- We’re committed to the environment and reducing waste, and regularly make donations of our glass offcuts and packaging to local schools and art clubs.

5- The Renault Master vans operated by Morley Glass will clock up to 100,000 miles every year delivering integral blinds and standard double-glazed sealed units to customers.

6- We manufacture 3,000 sealed units a week, 80% of which are supplied with Uni-Blinds® integral blinds in them.

7- We were the first company in the UK to achieve the BS EN 1279-6:2002 kite mark for manufacturing insulating glass units with ScreenLine® integral Venetian blinds inside.

8- We have three members of the Morley team currently embarking on NVQs with the help of North Lancs Training Group.

9- We are proud to be able to deliver nationwide, from Elgin to Port Isaac, as well as to customers in the Channel Islands and also in France.

10- We are the only UK integral blind manufacturer and supplier affiliated with the British Blinds and Shutter Association (BBSA) which operates the RoSPA Make it Safe campaign.

11- Our enlarged factory enables us to stock £1,000,000 of Screenline® components – the largest in Europe – and most parts can be supplied within 24 hours.

12- A common misconception of our integral blinds is that they’re difficult to install, when actually nothing could be further from the truth!

13- Thanks to our warm edge spacer bars, Uni-Blinds are suitable for A and B rated windows under the WER (Windows Energy Ratings) scheme.

14- Integral blinds aren’t only for living rooms and conservatories, they’re also an ideal option for ‘damp’ rooms such as kitchens due to being watertight. They are also the only viable sunshading option for bifolding doors.

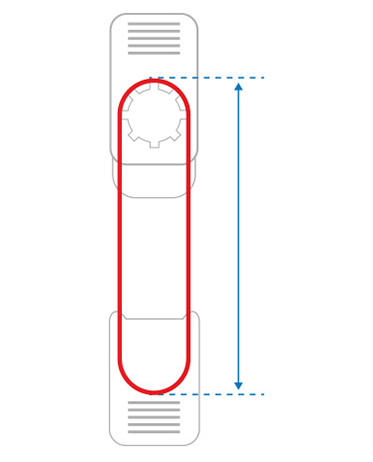

15- Installing Uni-blinds doesn’t have to mean replacing the entire window frame, they’re actually very easy to retrofit if desired. This includes our new SL16 slimline blind system, which is suitable for use in a 16mm cavity.

16- The rotating magnets we use inside our mechanisms that ensure the blinds are sealed and protected from dust have an impressive lifespan of over 100 years.

17- We pride ourselves on our customer service, and once stepped in to help a homeowner repair and replace their bifolding door after 10 years when it was accidently smashed.

18- No-one wants wonky blinds, so to prevent this happening with our Uni-Blind sealed units with ScreenLine integral blinds inside, Italian manufacturer Pellini incorporated an automatic levelling device, exclusively for our SV System.

19- Our motorised Uni-Blind® MB system benefits from the quietest ever brushless motor and plug-in diagnostics to speedily resolve any operational issues with ease.

20- We’re not the only ones who think we’re the bee’s knees, and last year we were named IGU Manufacturer of the Year at the National Fenestration Awards!