When it comes to working more sustainably, one thing all businesses should be able to do relatively easily is to reduce the amount of waste they send to landfill. But, to make this a reality we all need access to easy processes to ensure the by-products of our everyday operations can be diverted hassle-free and low cost – or free of charge – into the right channels for recycling.

Installers working on replacement window and door projects always face issue of disposing of the old products they remove, and all the different materials that entails – glass, timber, PVC, aluminium, metal hardware, gaskets, etc. But with the right support from the supply chain, there is no reason why we cannot deal with these post-consumer waste products effectively and deliver wider benefits to our communities as a result.

This is the thinking behind our CRUSH initiative. Since 2019, we have worked in partnership with Saint-Gobain Glass to collect and recycle the glass that installers of our Uni-Blinds integral blinds remove during their daily work. So far that has diverted more than 500 tonnes of glass away from landfill.

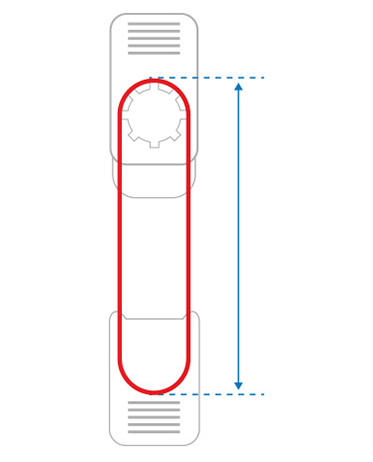

At the heart of the CRUSH initiative is our glass crushing machine which converts the post-consumer glass into glass cullet. This can then be used in place of virgin raw materials for the manufacture of new float glass, which is why Saint-Gobain Glass were keen to partner with us from the outset.

With the raw material production savings this makes, every tonne of cullet saves 300kg of CO2 emissions. That means the 500 tonnes of cullet already collected (up to June 2021) has saved 150,000kg of CO2 in 18 months – and those savings are increasing all the time.

But the benefits don’t stop there. The revenue generated from this high quality glass cullet is used to support good causes across Yorkshire through the Morley Glass GreenVision fund. This offers ‘green fund’ grants of £500 to charities who are dedicated to sustainability initiatives that deliver environmental benefits.

The direct and positive impacts on the environment also extend into making the manufacture of new glass more energy efficient. This is because the amount of energy needed by a furnace to melt recycled glass cullet is 30% lower than for virgin materials.